Bio-safe, Eco-friendly, High-strength Adhesive Material

Bio-safe, eco-friendly, high-strength adhesive material developed by Professor Byeong-Su Kim’s team

Development of an eco-friendly adhesive material that can withstand a weight of more than 30 kg with a minimal application, by maximizing hydrogen bonding

Applicable in fields such as electronic devices, automobiles, and bio-products

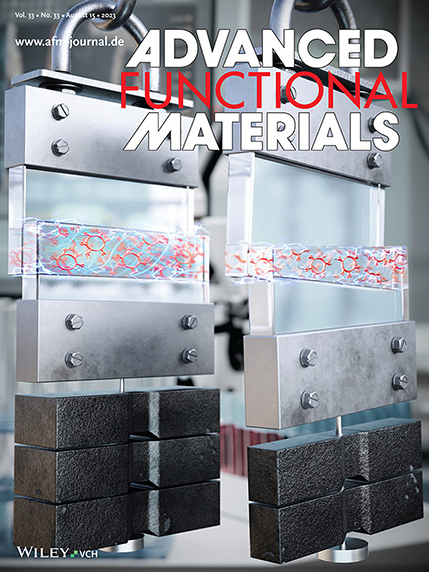

[Figure 1. Schematic diagram of a non-curing adhesive using hydrogen bonding developed by the researchers (cover paper of the August issue of Advanced Functional Materials)]

Professor Byeong-Su Kim’s research team from the Department of Chemistry at the College of Science, through joint research with Dr. Sang-Ho Lee's research team at the Korea Research Institute of Chemical Technology, developed a non-curing, bio-safe adhesive material that can withstand more than 30 kg with a minimal application, utilizing a method to maximize hydrogen bonding in polymer materials.

As regulations on hazardous substances are being strengthened worldwide, the adhesive developed by the research team is expected to be applied to a variety of industries, including household goods, electronic devices, transportation (cars, ships), and bio-products.

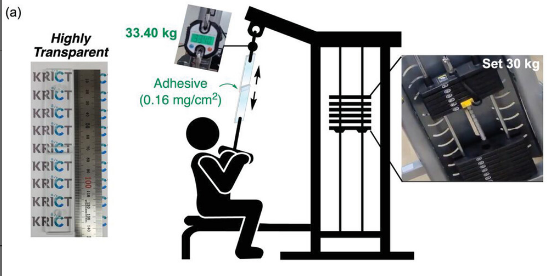

Most existing adhesives need to be hardened to increase adhesion, but they contain highly toxic substances and it is difficult to remove the remnants after use. Despite the rising interest in bio-safe non-curing adhesives because of the high toxicity of curing adhesives, it has been difficult to use them in the industry, as hydrogen bond-based non-curing adhesive materials have maximum adhesive performance of approximately 13 kg per 0.16 mg/cm2..

Accordingly, to solve the low adhesion performance of existing non-curing adhesive materials, the joint research team modified the polymer form into a structure that can maximize hydrogen bonding between adhesive materials. The two teams began research using polyether polyol, which is safe for the human body, as an adhesive material. At first, they succeeded in transforming polyether polyol into three shapes: ‘ring-branched, highly branched, and linear’. Among them, the long ‘linear’ structure exhibited the strongest hydrogen bonding.

Consequently, they added two more compounds to maximize hydrogen bonding. Firstly, a carboxylic acid functional structure was added that induces stronger hydrogen bonds. Polyether materials with the added carboxylic acid functional groups induced hydrogen bonding most effectively in a round ‘ring-branched’ structure rather than in the ‘linear’ structure, and showed excellent adhesion. Secondly, to further strengthen the adhesion, ‘linear’ polyether polyol, which has the strongest hydrogen bond among substances without carboxylic acid, was included.

As a result, in an experiment attaching a glass substrate, the adhesive withstood a weight equivalent to that of a curing adhesive at 33.4 kg per 0.16 mg/cm2, thus demonstrating an adhesive performance 2.6 times higher than that of existing non-curing adhesives. It demonstrated high adhesion not only to glass but also to other materials, such as iron and plastic that can induce hydrogen bonding.

[Figure 2. Advantages of polymer non-curing adhesive material with controlled hydrogen bond-based structure]

The developed eco-friendly adhesive material has the characteristic of hydrogen bonding, which allows it to be restored to its original state when heated to its break-point, with a force exceeding the adhesive strength, so it is highly recyclable. Toxicity testing revealed it is harmless to the human body, and it also has the advantage of being very easily removed using alcohol , which is often used in everyday life.

This research not only overcomes the limitations of existing non-curing adhesive materials by dramatically increasing adhesive performance, but also has advantages, such as being harmless to the human body, easy to recycle, and easy to remove. It is expected to be used in fields that require low weight bearing, including in electronic devices and automobile manufacturing, as well as in daily lifestyle supplies and bio-friendly products.

This research was conducted with support from the Basic Program of the Korea Research Institute of Chemical Technology, the Personal Basic Program of the Ministry of Science and ICT, and the Materials and Components Technology Development Program of the Ministry of Trade, Industry and Energy. The research results were published as the cover paper in the August issue of an international academic journal in the field of science and technology, 'Advanced Functional Materials' (IF 19.0).

Find out more:

Title of original article: Design of Topology-Controlled Polyethers toward Robust Cooperative Hydrogen Bonding

DOI: https://doi.org/10.1002/adfm.202302086

Journal: Advanced Functional Materials

Contact corresponding author: Prof. Byeong-Su Kim (bskim19@yonsei.ac.kr)

Recommended Articles

Professor Byeong-Su Kim

New study demonstrates that “deformable” electronics are not a stretch

Professor Yeonjin Yi