New study demonstrates that “deformable” electronics are not a stretch

As electronic devices continue to evolve, so do their capabilities and their potential fields of application. Flexible, stretchable, and deformable electronic devices are slowly but surely becoming a reality, with flexible displays having taken their place on the spotlight for a while. However, flexible electronic devices would not be useful only for some mundane gadgets; they would be key for multiple next-generation technologies. For example, stretchable electronic devices could be used in wearable healthcare devices, artificial muscles, implants, and so on.

Making the fabrication of such devices a reality is challenging, though, because manufacturers demand novel materials and conductors with a combination of properties that cannot be met simultaneously with conventional materials. More specifically, it is very difficult to create a stretchable conductor that offers high electrical conductivity even under great mechanical strain. Additionally, the fabrication process for such a conductor should be easy to scale up to allow for mass production. Otherwise, manufacturers would not be able to use them and no one would benefit.

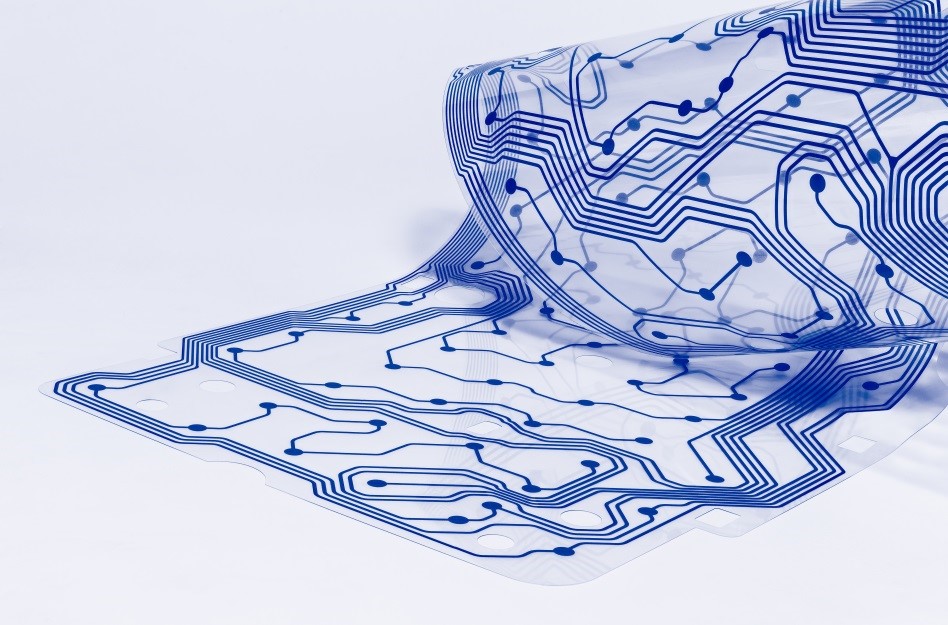

Advances in flexible and stretchable conductors are critical for the development of deformable electronics, which could be used in a variety of medical applications.

Advances in flexible and stretchable conductors are critical for the development of deformable electronics, which could be used in a variety of medical applications.

(Photo Courtesy: Shutterstock)

Luckily, a joint research team from Yonsei University, POSTECH, and the University of Michigan has developed a novel flexible and stretchable conductor by combining well-established fabrication techniques into a novel approach. This flexible conductor consists of multiple layers of a polymer (polyurethane), with each layer having a certain “concentration” of gold nanoparticles in order to allow electricity to flow.

Surprisingly, the use of conducting nanoparticles in stretchable polymers to grant them conducting properties is not completely new. “The main problem with such approaches is that there is a trade-off between stretchability and conductivity, which limits their practical use in, for example, batteries ,” explains Prof Byeong-Su Kim, lead researcher from Yonsei University. However, in the novel approach presented by the team, concentration gradients of gold nanoparticles are created in the multi-layered conductor. The team found out that, by tuning these gradients, they could create a flexible conductor with remarkable conductivity and mechanical and electrochemical stability, thereby overcoming the limitations of previous materials.

How is it possible? When the material is not under strain, the layers with a very high concentration of gold nanoparticles behave like normal wires. When the material is stretched, the gold nanoparticles undergo a process of self-organization within the stretchable polymer that forms alternative conducting pathways in the material, helping to maintain its conducting properties. By leveraging this phenomenon and through careful layer-by-layer design and assembly, the proposed gradient multi-layered conductors can be fine-tuned to be as flexible and conductive as needed for each particular application.

The team demonstrated that their flexible conductor could be used in a stretchable lithium-ion battery. The success of the proposed approach paves the way for the development of similar techniques for a myriad of novel materials. In the words of Prof Kim: “The materials engineering concept of our stretchable conductor can be generalized to and combined with a variety of nanoscale components ”. In addition, the synthesis process is relatively simple and should be easy to scale up. Hopefully, this research will bring us closer to many next-generation medical devices, ultimately benefiting millions of patients and healthcare professionals worldwide.

Updated in July 2019

Recommended Articles

Professor Jinwook Kim

Smectite-to-illite transformation: Microbes could hold key to oil exploration

Professor Yeonjin Yi