Artificial materials for developing low-cost optical devices

New research demonstrates macroscale materials having optical properties that are modifiable by mechanical compression, paving the way for industrial-scale production of advanced optical devices.

The study—“Scalable variable-index elasto-optic metamaterials for macroscopic optical components and devices”—published in Nature Communications was carried out by a group of researchers including Dr. Kyoungsik Kim of Yonsei University. They developed a method to build large, low-cost, and mass-producible advanced optical devices by using an artificial material called “metamaterial” that changes its refractive index when subjected to mechanical stress. This material was used to demonstrate two macroscopic-scale optical devices that have so far been achieved only in the microscopic scale.

These artificially engineered materials can exhibit properties difficult to observe in nature, such as a refractive index varying along the cross section of materials. So far, metamaterials have been fabricated by painstakingly shaping the microscopic structures of materials through nanofabrication techniques. Dr. Kyoungsik Kim shares, “optical metamaterials are limited to a microscopic level because nanofabrication techniques are expensive and time-consuming.” Such microscopic optical devices require artificial light couplers to interact with light, and they can only be used for a limited wavelength range. These limitations motivated the researchers to look for a simple and commercially viable solution to produce advanced optical devices. “Optical metamaterials offer a whole new range of opportunities in photonic markets as they can be produced on a large scale with affordable prices,” Dr. Kim adds.

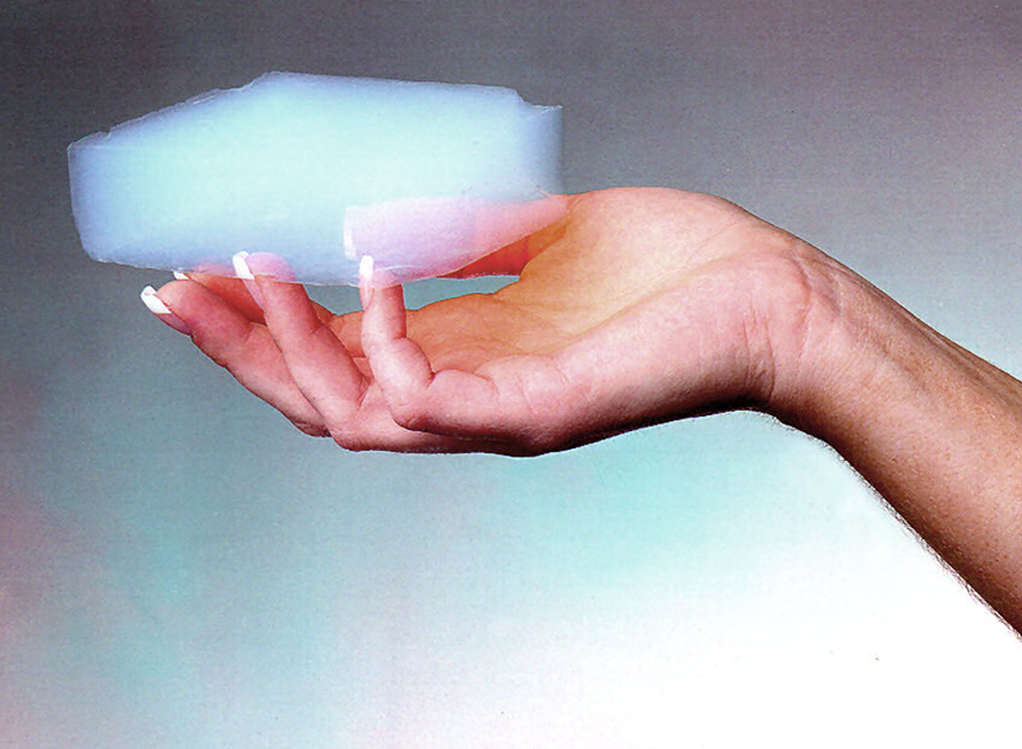

In their experiments, the researchers used a synthetic, porous, and extremely light material called an aerogel. This is essentially a gel formed with air (or a gas) instead of a liquid. They made compressible, transparent, and homogeneous aerogel chunks measuring approximately 5 cm across, filled with nanometer-sized pores. The refractive index of the aerogel varies with the extent of mechanical compression, and the aerogel is transparent in the entire visible spectrum. Thus, it can be used to make optical devices with a graded refractive index, which means that the refractive index within the material continuously changes along one direction.

As practical examples, the researchers demonstrated two optical devices—a transformation-optics wave bender and a Luneburg lens—using compressed aerogels. The wave bender is an arc-shaped aerogel slab that can guide light from one end to the other, whereas the Luneburg lens is a disc-shaped aerogel slab that can redirect and focus light. These devices were formed by compressing the aerogel using molds to achieve the required graded refractive index. The sizes of these components were much larger than previously developed metamaterial devices. This means that light can be manipulated in a much larger region, making artificial light couplers unnecessary. Both these optical components were shown to work well in the entire visible spectrum.

For the first time, low-cost and mass-producible macroscopic-scale metamaterials were produced. The researchers say, “Our method allows natural light to interact directly with metamaterial devices without any additional coupling components, opening the door to industrial applications of optical metamaterials in general, and transformation optics in particular.” This technology is expected to lead to the industrial-scale production of adaptive lenses for advanced miniaturized cameras, machine vision, lidar-based technologies, and energy harvesting.

Recommended Articles

Professor Jong-Hyun Ahn

Novel technique for producing high-resolution micro-LED displays

Professor Seong Chan Jun

Professor Donghyun Kim

Array of hope: Up close and personal with mitochondria in neurons